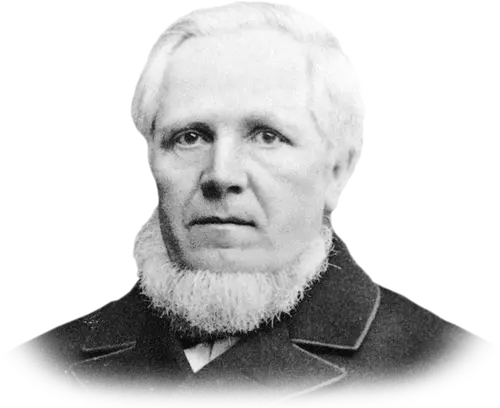

Pehr Adolf Janson

THE FIRST GENERATION

The Christmas of 1839 was a very painful time in the little house on the outskirts of Örebro where nine-year-old Pehr Adolf and his six siblings lived. Their father, Johan Janson, had just announced to them that their mother had passed away, exhausted by the harsh living conditions of the time. Poverty was a constant in Sweden throughout the 19th century; in fact, a third of the population emigrated to the United States in the hope of finding a better life. Pehr Adolf's father chose to stay in Sweden and, as the children grew, he instilled in them the importance of developing themselves to the fullest in their trade and also as merchants:

"I WANT YOU TO BE BETTER THAN ME. TO LEARN AND MASTER THE PROFESSION YOU CHOOSE IN ORDER TO GIVE PEOPLE SOMETHING THEY NEED. AND THAT, IN THIS WAY, YOU CAN ALWAYS TAKE CARE OF YOUR LOVED ONES."

Pehr Adolf becomes an ambitious young man whose goal is to be a master saddle maker. This decision will not only change his life but also the lives of his children and several future generations. At the age of eighteen, Pehr Adolf becomes an apprentice and begins to make exceptional saddles with Swedish leather fittings.

Four years later, on 22 March 1852, he received from the hands of the King of Sweden the certificate of master saddle maker. In addition to making saddles and harnesses, a master is also dedicated to making mattresses with the finest horsehair, as well as leather goods. The best craftsmen knew how to make these items with the utmost precision but also at great speed, demonstrating a passionate spirit of excellence.

For Pehr Adolf, it was a great pride to make his dreams and those of his father come true. Shortly after, he married the love of his life: Elisabeth Charlotta Carolina Almblad. The couple moved to the small town of Hed, on the outskirts of Köping (pronounced "Sherping") with their three children, Adolf Fredrik, Ida Elisabeth, and Per Thure. The two boys would soon follow in their father's footsteps, becoming saddle makers. Adolf Fredrik would eventually leave the trade and become a politician. And a politician very ahead of his time, as he actively and passionately fought for gender equality.

Per Thure Janson

THE SECOND GENERATION

Per Thure ensured that the tradition of family mastery remained alive at the end of the 19th century, and to this end, he took over the saddle-making business from 1885. By then, the family had long been following the wise advice that each generation should be better than the previous one, so that they could take care of their loved ones.

Educated in the same way as his father, Per also quickly adapted to the new times and, when the First World War brought the first automobiles to Sweden, he had the good idea of focusing on manufacturing mattresses, seats, and horsehair cushions.

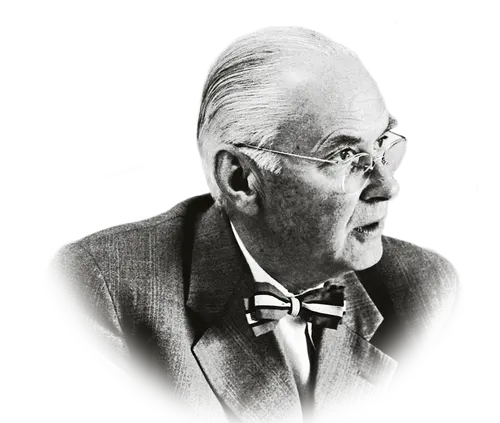

David Stefanus Janson

THE THIRD GENERATION

Per Thure and his son David Janson will take the tradition of saddle-making masters a step further, growing the production of saddles and harnesses while expanding the family business to manufacture more and more beds. With the advent of the automobile, Janson was able to predict future changes in the world of transport and, in 1917, decided to focus entirely on beds. The eve of the summer solstice celebration was the date when Paul Janson, Janson's artist cousin, drew the first Hästens logo.

A horse was incorporated into the company name as a tribute to its tradition as saddle makers, becoming a defining symbol of Hästens' identity. That same year, there were sudden problems with material shortages. The authentic horse tail hair, which had always been the main filling material for the beds, became difficult to find in the quality and quantity needed to meet the demand for high-quality handmade beds. In order to achieve this quality, the horse hair must be meticulously selected, washed, boiled, centrifuged, burned, and thoroughly cleaned to bring out its suitable filling properties. Janson and his father resolved these issues by opening their own horse hair processing plant, thereby ensuring the high quality of Hästens.

David Janson recalls: "My father was an old-school craftsman; for him, the words quality and craftsmanship were almost sacred. This attitude was etched into my mind and that of everyone who worked for the company. The products we manufactured aimed to earn the respect of the consumer. That is the ideal we have always aspired to. At that time, the working conditions of a saddle maker were far from perfect, and the future did not look any brighter. Quite the opposite, in fact. But we considered how to expand the narrow framework in which we worked, and whether we should move from small-scale craftsmanship to a modest-sized small business. At that time, it was just my father, a few craftsmen, and me. To progress, we had to overcome the restrictive limits imposed by pure craftsmanship and opt for more industrial methods. This led us to think about complementing our operations with a horsehair spinning plant. We may have had within us what some describe as "that little spark," so we set up our horsehair spinning plant. The year of expansion was 1917; I was 25 years old at the time. Obviously, due to the World War, the lack of raw materials, and the great difficulties in obtaining the appropriate machinery, it was a very complicated time to launch an initiative like this. And things did not improve when my father fell ill shortly afterwards. The situation seemed frankly dire, but in Västmanland, which is the region of Sweden we come from, we are famous for our will and stubbornness. Perhaps it was nothing more than pride that made us endure!"

Three years after deciding to focus exclusively on beds, and having set up their own spinning plant, Hästens purchased twenty tonnes of horsehair to meet production demand. The master chair makers were obsessed with quality in their quest for the best possible product, with the "spirit of excellence" driving them to go beyond existing conditions and establish their own standard. In search of the best materials, they travelled the world, including Egypt, where the highest quality horsehair is found. From that moment on, horse tail hair from the gleaming Arabian horses was transported to Köping to be washed and clarified in the fresh, clean waters of the river that runs alongside the factory.

The small town of Hed soon became insufficient for the expansion of the family business, and in 1924 Janson considered relocating to Stockholm. In the capital, there were more customers, and Hästens' sales in the department store Nordiska Kompaniet, located in the city centre, were already considerable. A manufacturing plant was sought in Sundbyberg, near Stockholm, but a passionate romance prompted a change of plans and led Hästens to choose the town of Köping. David Janson had fallen in love with Astrid, a girl born in Köping, and the following year, Solveig, the couple's first child, was born. Since then, the city has been the operational centre of Hästens.

In 1926, the company began manufacturing duvets and pillows using the finest down and feathers available, thus complementing its bed manufacturing business.

In the 1930s, the family noticed a very significant change in sleep culture. Until then, many had managed to spend the night on a sofa, but more and more were investing in a furnished bedroom and a proper bed. On 13 January 1935, the Hästens logo was registered as a trademark in Sweden, a brand that is still in effect today.

By the mid-1940s, Hästens had grown to the point of needing larger facilities. Janson not only wanted to expand, but also wanted to create a new dream factory. At the end of that decade, he contacted Ralph Erskine, who was then a little-known architect. Erskine's style attracted Janson, who proposed that he design the new factory. The result was a building that bore no resemblance to a conventional factory. Initially known as "the Tivoli," its unique design, with elegant lines and light, arched shapes, quickly made it an icon among Swedish architects.

As a promise of quality and durability, Janson introduced a 25-year guarantee for all beds. Their intention was to produce beds that would be just as comfortable (or more) twenty-five years after they had been first used.

When Hästens celebrated its centenary as a bed manufacturer in 1952, King Gustaf Adolf VI of Sweden granted it the title of Supplier to the Royal Court and visited the factory in Köping the following year, in formal recognition of the company's high-quality products. That same year, the Swedish American Line purchased Hästens beds for its cruise ship M/S Gripsholm. Hästens began to gain a great reputation for its superior quality.

THE FOURTH GENERATION

Solveig, daughter of David Janson, was the financial director of the company for many years in the mid-century, and in 1963 she became responsible for operations alongside her husband, Jack Ryde, with the support of two younger sisters, Ethel and Yvonne. The business expanded rapidly in various directions to also include the manufacture of furniture, seating, and back cushions.

Jack Ryde, an enthusiast of art and design, had the idea to create a distinctive and high-quality pattern that would represent the brand. In 1978, he designed the Hästens Blue Check and unveiled it at a furniture fair in Sweden. His eye-catching design soon became the subject of criticism from the Swedish press. The freshness of his blue and white pattern clashed head-on with the prevailing tones of the seventies (browns, greens, oranges); it was completely different from anything that had been seen before on a bed. But history has ultimately vindicated him. Jack Ryde challenged and transformed the status quo, along with the traditional image and function of beds.

Solveig Ryde & Jack Ryde

Jan Ryde

THE FIFTH GENERATION

In 1988, ten years after the introduction of the Blue Check, Jan Ryde took the reins of the company. Like his grandfather, Jan Ryde's journey at Hästens is marked by his love story with the most beautiful girl he had ever met: Anne-Lie, from Köping. After developing a career at the Technical Faculty of Linköping, where he taught industrial economics students and prepared for his doctorate, Jan decided to leave university life behind and return home to take charge of Hästens' operations and start a family.

Currently, one of their four young children has already joined the family business. Under Ryde's leadership, the company has focused its ambitions on its core activity, which has greatly increased the global demand for fully natural beds with check patterns.

In 1995, King Carl Gustaf XVI reappointed Hästens as suppliers to the Royal House.

The demand for Hästens beds continued to rise and, in 1998, in light of Hästens' ongoing expansion, it was decided to enlarge the factory. And fifty years after designing the first dream factory at the beginning of his career, the now-famous architect Ralph Erskine was once again tasked with designing its extension.

Jan has proudly introduced the tradition of craftsmanship in the 21st century, and today this small family-owned company has expanded its borders to include 45 countries across Europe, Asia, and America. The beds continue to be handmade using the same natural materials and the same spirit of excellence as when Pehr Adolf made his first beds 170 years ago.

Hästens has had the honour and privilege of serving as the official supplier to the Royal Court of Sweden for three generations.

On the verge of reaching a hundred years since its founding, Hästens was appointed supplier to His Majesty the King of Sweden in 1952 by Gustaf VI Adolf, and since then we have not ceased to supply products to the Royal House.

The requirements for such an appointment are very strict, and the distinction must be renewed each time a new king is appointed. The title of Supplier to the Royal Household is synonymous with Swedish quality and top-tier Scandinavian design, a badge that we carry with pride and honour.